What is Lean?

The Lean method, developed by the Japanese company Toyota, is also known as the Toyota Production System (TPS). This approach has its roots in the "Lean manufacturing" movement of the 1950s. However, with the publication of Lean Software Development: An Agile Toolkit in 2003, it is now considered an integral part of Agile software development methodology. Lean Software Development is a concept that emphasizes optimizing efficiency and minimizing waste in the software development process.

Check Out Our Related Trainings Now

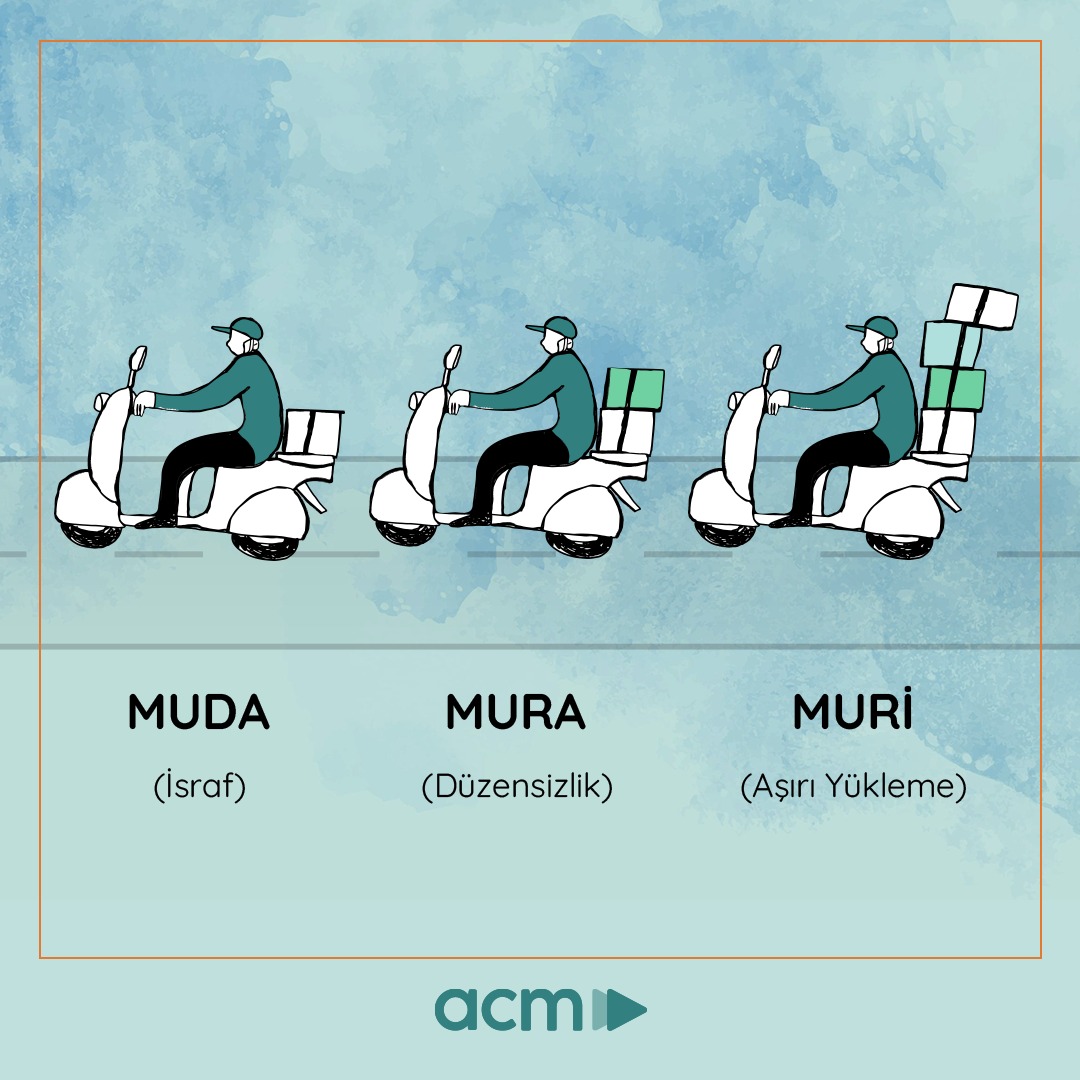

The Lean method aims to reduce waste in the production process by using the basic methods defined in three categories as Mura, Muda, and Muri.

Mura: It aims to reduce unnecessary gaps in the production process. These gaps can be due to waiting times and high stock levels in the production process. Aim of Mura is to streamline the production process and reduce waiting times.

Muda: It aims to eliminate the steps in the production process that do not create any value. These steps can be unnecessary movements, misplaced equipment, or processes in the production process. Aim of Muda is to make the production process more efficient and reduce waste.

Muri: It aims to reduce overload in the production process. This allows workers to work with just the right amount of load so that they can get their work done without hassle. Aim of Muri is to increase productivity by protecting the health of employees.

Waste refers to steps in the production process that do not create any value. Eliminating these steps, makes the production process more efficient, thus reducing costs and increasing customer satisfaction. In addition, while increasing the efficiency and speed of the production process, it also increases the motivation of the employees.

Lean manufacturing combined with an Agile mindset can be used to deliver value and create impact in the following ways.

Prioritizing customer needs: TPS emphasizes the importance of understanding and meeting customer needs. By combining Lean manufacturing with an Agile mindset, organizations can gather customer feedback and continually improve products and processes to meet these needs.

Emphasis on continuous improvement: Lean manufacturing is built on the principle of continuous improvement, and when combined with an Agile mindset, organizations can use TPS tools and methods such as Kaizen to continuously optimize processes and eliminate waste.

Focus on flow: TPS emphasizes the importance of creating a seamless flow of materials and information throughout the manufacturing process. Organizations can also focus on creating flow in their development processes by combining the Lean manufacturing approach with the Agile mindset.

Promoting collaboration and teamwork: TPS emphasizes the importance of teamwork and collaboration to increase efficiency and quality. By combining Lean manufacturing with an Agile mindset, organizations can foster collaboration and teamwork to deliver value and create impact.

Emphasis on adaptation: TPS is a flexible system that can adapt to changing customer needs and market conditions. By combining Lean manufacturing with an Agile mindset, organizations can become more adaptable and responsive to change.

By combining lean manufacturing with an Agile mindset, organizations can deliver value and create impact more efficiently by focusing on customer needs, continuously improving, creating flow, collaborating, and adapting to change.

Comment(s)